What is the Process to Create a Customized Piece of Jewelry?

When you make your appointment with one of our professional jewelry consultants, you have begun the process that will deliver a piece of the finest quality and is crafted with the utmost care. A custom-designed piece means your jewelry is precious and one of a kind - a keepsake family heirloom that is never compromised. Here are the steps in creating a treasure you will always cherish.

Step One - Consultation

Whether you are interested in an engagement ring, wedding band, pendant, bracelet, necklace or a different piece or set, we’ll sit down and help you create exactly what your heart desires. If diamonds are incorporated, we’ll discuss the shape, carat weight, and other criteria. Once the diamond(s) is selected, we’ll help you decide on a setting. You may want to bring in images, pictures, or a simple drawing to show what design you have in mind. We can also work with you to create a drawing from scratch.

Step Two - CAD Design

Once the piece has been conceptualized and discussed, we create a customized computer-aided design (CAD). The CAD file provides you with a feel of what your piece would look like. During this process you can request changes to ensure your jewelry is exactly what you have in mind, with all the design aspects you desire. Our designers can incorporate just about any changes to the CAD you can imagine.

Step Three - Wax Growing

Wax growing means a 3-dimensional wax of your piece is grown from the CAD file. Only the latest rapid prototype technology is used. If desired, you can now preview the wax before the final casting.

Step Four - Casting & Finishing

Our production department takes the approved wax and attaches it to a tree using a hot wax pen. The wax tree is then covered with a flask and filled with investment. This is similar to plaster. The investment dries and the flask is inserted into an oven to burn out the wax (called lost wax casting). When the wax is burned out, every detail of the piece has left an imprint in the investment (which now looks like gypsum/drywall). The desired metal is melted and forced into the investment mold. When it cools it forms the unfinished piece. The piece is then broken out of the investment, clipped from the tree, and sent to the finishing department for polishing and diamond/stone setting. The piece is now complete!

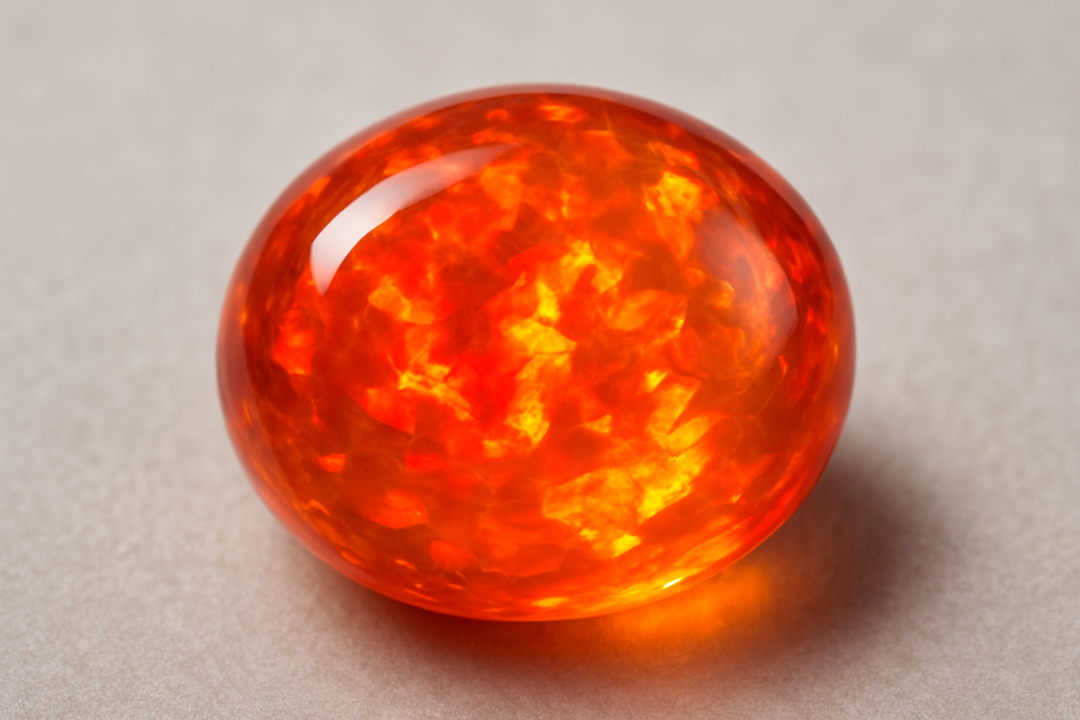

In business for over 40 years, Legacy Jewelry honors the stories of gemstones and enjoys bringing them into people’s lives. At Legacy, we work with you to create customized jewelry. In addition, we offer appraisal and estate services and sell the finest estate & new jewelry backed with a GIA Gemologist's signature of approval - view our collection here. For same day service or to make an appointment, give us a call at 949-230-1069.

Leave a comment